SEE Institute's 2030 Net Zero Building

what is unique about our building?

Located in the Sustainable City

SEE Institute is located in The Sustainable City (TSC), a residential community that represents an illustrative example of best environmental enhancement practices and various smart solutions blending together which allow not only to deliver a high quality of life to its residents but to be a living lab integrating research, innovation and experiential learning.

Hybrid Cooling System & Biogas Plant

Energy Efficiency

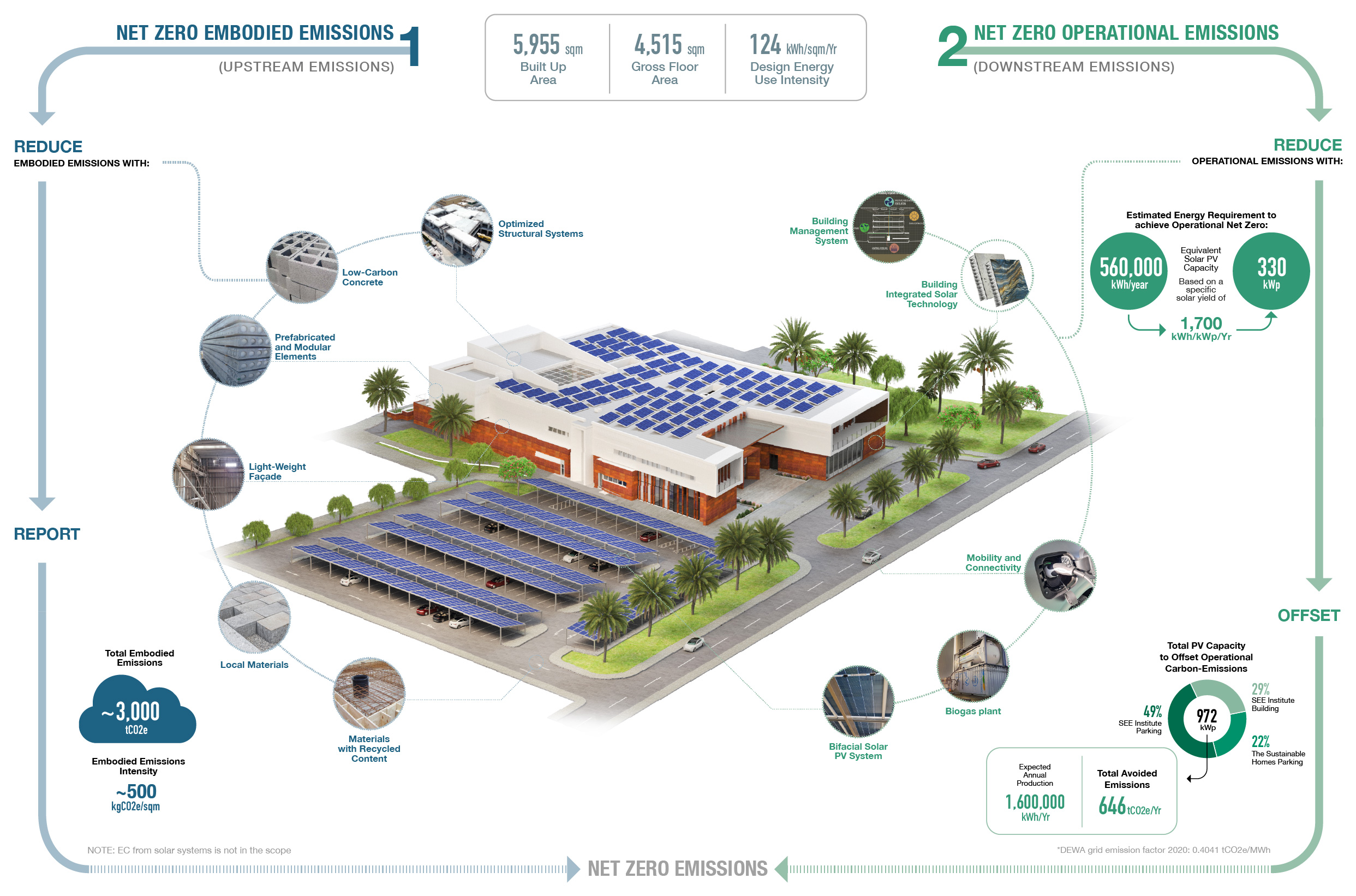

SEE Institute employed an integrated approach to energy demand-side management through passive and active design strategies, to achieve 100 kWh/m2/year of Energy Use Intensity. This includes orientation to the North, a highly insulated building envelope, a hybrid cooling system, and a building management system. Bifacial PV panels on the rooftop and adjacent car parks are able to meet 300% of the building’s annual electricity demand, therefore offsetting GHG emissions from the building’s day-to-day operation beyond just electricity consumption.

Materials

Low-carbon concrete produced locally, mixes, prefabricated structural elements and materials with recycled content allowed to minimize embodied carbon of the building compared to a business-as-usual practice by approximately 26%.

Why is Net Zero Important?

Buildings represent 39% of global greenhouse gas emissions, including 28% in operational emissions and 11% in building materials and construction. Reducing carbon emissions in buildings will be critical to achieving the Paris climate goals and achieving net zero emissions by 2050.

Efficient, zero carbon buildings take advantage of available, cost-effective technology to reduce emissions while increasing health, equity and economic prosperity in local communities. A whole lifecycle approach implies a balancing of short and long term emissions.